Your blog feed for digital manufacturing resources, in-depth features, and industry news.

Shifter PRNDL Transmission: A Key Component in Modern Automotive Design

Table of Contents

Introduction

In the world of automotive engineering, the Shifter PRNDL transmission system plays a critical role in the driving experience.

It’s the interface that connects the driver with the vehicle’s transmission, allowing for smooth gear shifts and overall vehicle control. But how does it work, and why is it so important? Here’s a quick breakdown of the Shifter PRNDL transmission and its impact on the automotive industry.

What is Shifter PRNDL?

The Shifter PRNDL refers to the gear selector panel commonly found in vehicles, usually located between the driver and passenger seats or on the steering column. The term “PRNDL” stands for:

- P – Park

- R – Reverse

- N – Neutral

- D – Drive

- L – Low (sometimes available for specific needs like hill driving)

These settings are the primary interface that allows drivers to choose the appropriate driving mode for different situations, whether it’s parking, reversing, driving forward, or shifting into low gear for more power or engine braking.

How Does Shifter PRNDL Transmission Work?

The Shifter PRNDL is directly linked to the vehicle’s automatic transmission system, which automatically adjusts the gear ratios based on speed and throttle input. When the driver moves the gear lever to a specific mode on the PRNDL, the transmission responds accordingly:

- In Drive (D) mode, the transmission will automatically shift through the gears based on vehicle speed and acceleration.

- In Reverse (R) mode, the transmission switches to reverse gear for backing up.

- Neutral (N) disengages the engine from the wheels, allowing the car to roll freely.

- Park (P) locks the transmission and prevents the vehicle from moving.

- Low (L) is used for driving at slower speeds, often used for better control on steep inclines or declines.

The communication between the Shifter PRNDL and the automatic transmission ensures smooth transitions between gears and provides the driver with control over how the vehicle performs.

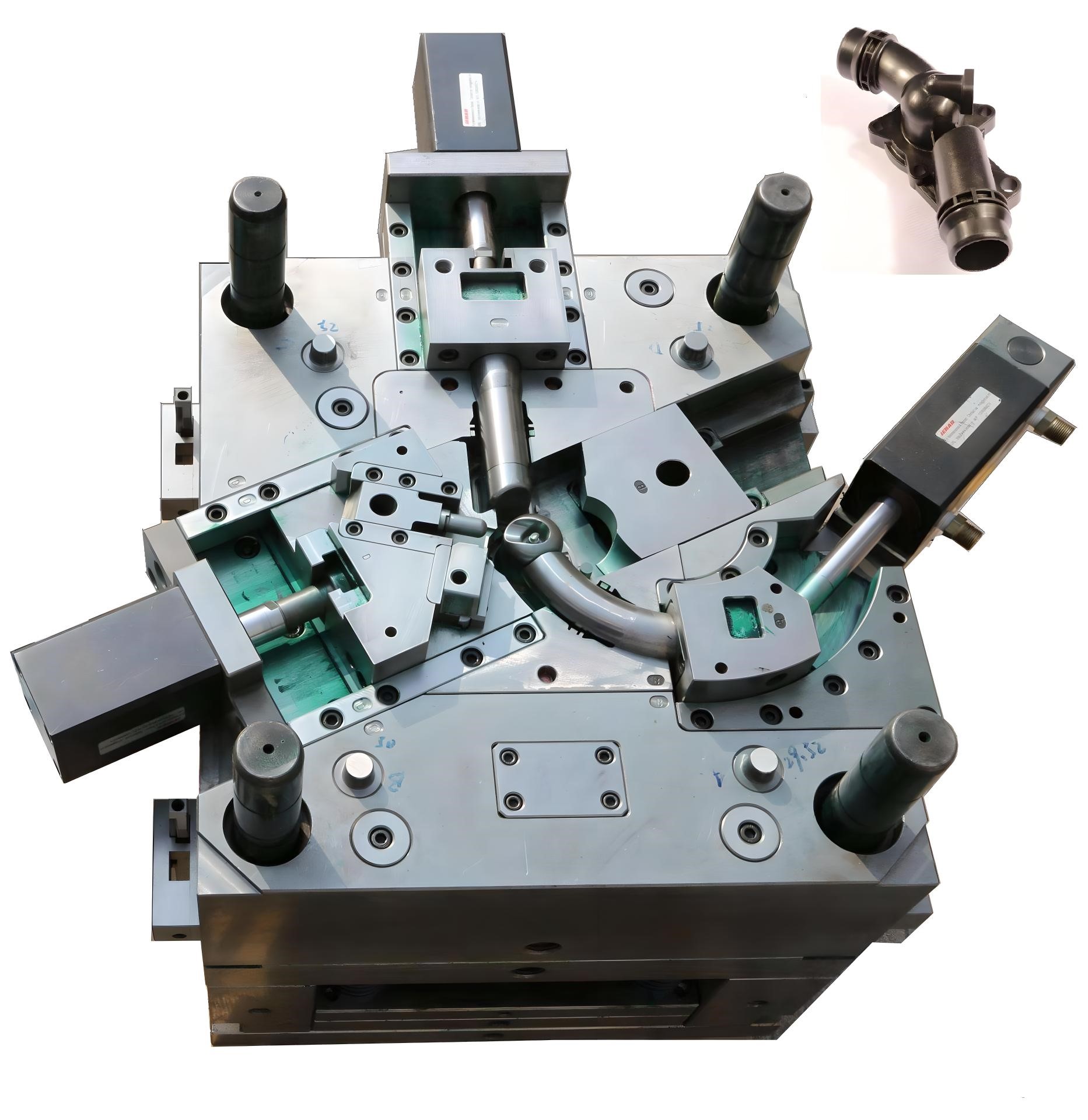

The Role of Plastic Injection Molding in Shifter PRNDL Components

The Shifter PRNDL system isn’t just about the lever—it involves several precision-made components that work together to ensure smooth operation. This is where plastic injection molding plays a key role.

Plastic injection molding offers a number of benefits for manufacturing Shifter PRNDL components, including:

- Precision: Injection molding allows for the creation of highly precise and complex parts, ensuring that each gear selector functions flawlessly.

- Durability: Plastic parts made through injection molding are lightweight yet durable, offering long-term performance under heavy use.

- Design Flexibility: With plastic injection molding, manufacturers can create custom designs, allowing for sleek, ergonomic, and modern Shifter PRNDLs that meet the aesthetic and functional needs of vehicle manufacturers.

- Cost-Effective: Injection molding is an efficient manufacturing process that produces large volumes of parts quickly, making it an ideal solution for the automotive industry.

Why Shifter PRNDL is Evolving

The automotive industry is constantly advancing, and so is the technology behind the Shifter PRNDL system. Modern vehicles are incorporating more advanced features into their transmissions, including:

- Electronic Shifters: Many newer cars are replacing mechanical levers with electronic Shifter PRNDLs, which offer smoother and more intuitive shifting.

- Push-Button Shifters: Some vehicles have adopted push-button or rotary dial shifters, further reducing the complexity of traditional gear selectors.

- Integrated Smart Features: Some systems even integrate advanced features like automatic gear shifting, allowing the vehicle to adjust to driving conditions without driver input.

As vehicle designs continue to evolve, so do the components that make them run. The Shifter PRNDL system, while rooted in traditional mechanical operation, is being integrated into smarter, more advanced transmission systems.

The Future of Shifter PRNDL and Transmission Systems

With the rise of electric vehicles (EVs) and autonomous driving technologies, the role of the Shifter PRNDL is likely to continue changing. In EVs, traditional gear shifting may become less relevant, as many electric drivetrains don’t require complex transmission systems. However, the design and functionality of the Shifter PRNDL system will still play a crucial role in maintaining driver comfort, control, and the overall driving experience.

Conclusion

Conclusion

The Shifter PRNDL transmission system is an essential component in modern vehicles, ensuring that drivers can control their car’s movement safely and effectively. With advancements in automotive technology, the Shifter PRNDL is evolving to meet the needs of smarter, more efficient vehicles. Plastic injection molding plays a critical role in producing high-quality, durable, and cost-effective Shifter PRNDL components, enabling manufacturers to create more innovative designs that enhance the driving experience.

- Aerospace

- Agriculture

- Alternative Energy

- Automotive

- Building and Construction

- Chemical

- [email protected]

- +86 153 0262 2329

- Mon-Sun 8:00-22:00